Inventory Order Management Software: Costs vs. Benefits

Efficient inventory management is crucial for food suppliers looking to reduce costs, optimise stock levels, and improve customer satisfaction. Inventory order management software streamlines operations by automating stock tracking, order processing, and demand forecasting, ultimately increasing profitability. By examining key features, operational efficiencies, and real-world case studies, food suppliers can determine whether investing in inventory management software is a strategic move for long-term success.

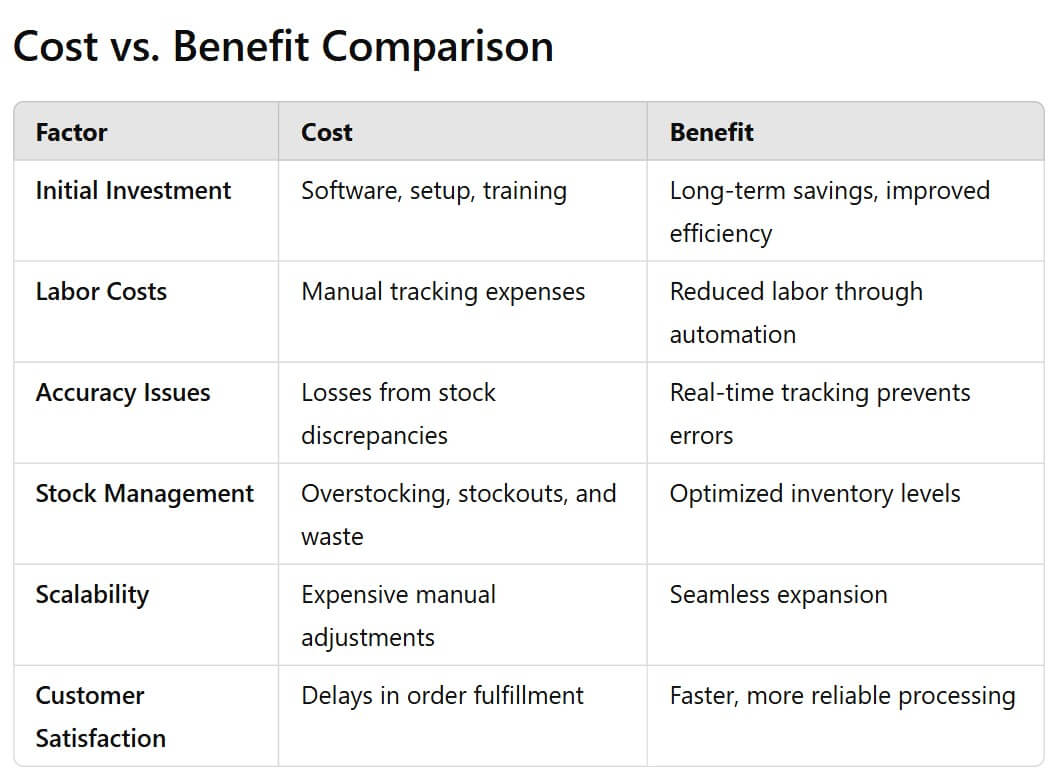

This article explores the costs and benefits of implementing such software, comparing manual inventory management with automated solutions to highlight the return on investment (ROI).

The Cost of Manual Inventory Tracking

For food suppliers, inventory order management software simplifies operations by consolidating order tracking across multiple sales channels, offering real-time stock updates to prevent shortages or excess inventory, and automating critical tasks such as reorder alerts, invoicing, and shipment tracking. By reducing manual processes, businesses can minimise errors, enhance efficiency, and optimise supply chain management.

Manual inventory tracking comes with hidden costs that can significantly impact business operations, such as:

- Higher Labor Expenses – Employees spend hours on repetitive tasks like counting stock, updating records, and reconciling discrepancies, increasing payroll costs.

- Stock Inaccuracies – Human errors in data entry or miscalculations can lead to incorrect inventory levels, resulting in stockouts, overstocking, or lost sales.

- Increased Food Waste – Without real-time tracking, perishable goods may expire before being sold, leading to financial losses and compliance issues.

- Reduced Productivity – Time spent on manual tracking takes employees away from higher-value tasks such as supplier negotiations, quality control, and strategic planning.

- Slower Decision-Making – Outdated or inaccurate data makes it difficult to forecast demand, plan purchases, and respond to market changes in a timely manner.

Read Real Time Inventory: A must for Food & Beverage Wholesaler

How Inventory Order Management Software Drives ROI for Food Suppliers?

Investing in inventory order management software delivers measurable returns by improving efficiency, reducing costs, and enhancing customer satisfaction. By automating routine tasks, food suppliers reduce labor costs, eliminate data entry errors, and free up employees to focus on strategic operations. Real-time analytics provide insights into stock movement, sales trends, and order accuracy, allowing companies to make data-driven decisions.

Key Benefits:

- Real-Time Inventory Tracking – Prevents stockouts and food waste by providing up-to-date stock visibility and expiration date management.

- Automated Reordering – Reduces manual errors by triggering purchase orders when inventory reaches preset thresholds, ensuring perishable items are stocked appropriately.

- Seamless Integration – Connects with ERP, e-commerce, and accounting systems for smooth data flow, enabling better financial planning.

- Demand Forecasting – Uses historical data and analytics to optimise stock levels, reduce spoilage, and minimise unnecessary storage costs.

- Multi-Channel Support – Centralises order management across various sales platforms, improving fulfillment speed and reducing delivery delays.

Best Inventory Management Systems for Wholesale Food Suppliers

Scalability & Expansion Support

For growing food suppliers, scalability is essential to ensure smooth operations as demand increases. Inventory order management software supports expansion by:

- Automated Order Allocation – Assigns stock efficiently across different locations to streamline fulfillment and prevent delays.

- Multi-Warehouse Management – Optimises stock distribution across multiple facilities, reducing shipping times and costs.

- E-Commerce & Logistics Integration – Connects with online marketplaces, third-party logistics providers, and shipping carriers for seamless order processing.

- Enhanced Inventory Accuracy – Reduces errors and discrepancies, ensuring real-time visibility and better decision-making.

What is the Role of Inventory Management in the Wholesale Food Distribution?

If your business struggles with tracking inventory, frequent stock discrepancies, or time-consuming manual processes, investing in inventory order management software can be a strategic move. This software streamlines operations by automating stock tracking, reducing errors, and integrating with existing systems like e-commerce platforms, accounting software, and supply chain management tools.

While there are upfront costs for licensing, implementation, and training, the long-term benefits—such as lower labor expenses, fewer stock-related losses, improved cash flow, and greater scalability—far outweigh the investment. With better forecasting, reduced waste, and smoother workflows, food suppliers can increase efficiency and profitability.

Open Pantry offers specialised inventory solutions for food suppliers, ensuring real-time stock visibility, automated reordering, and waste reduction. By optimising inventory and integrating with supply chains, Open Pantry helps businesses scale efficiently while reducing costs and maintaining accuracy.